CUTTING SOLUTIONS FOR SLITTING AND CUT TO LENGTH

Contact us for help?

Contact with us through our representative or submit a business inquiry online.

Products and Cutting Solutions for Slitting and cut to Length Systems

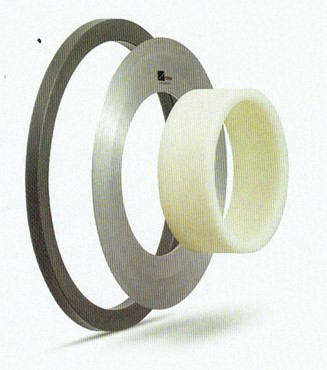

Circular Products

Circular products such as rotary slitter knives, strippers, spacers, etc., are used in slitting lines for cutting and slitting the greatest variety of materials. Dimensions, materials, hardness and rubber coating all depend on the material to be cut. The precision of the tool with regard to the thickness tolerance, the flatness, parallelism, surface finish on the one hand, and the properties of the material processed, the arbor set up, the configuration parameters of the slitting line on the other hand, as well as, of course, the machine operators, are all crucial factors in the quality of the cutting results

Straight Products

Scrap chopper knives, used for the shredding of the waste strips caused by trimming, are subjected to very high mechanical stress. As a rule, the strips or bands are cut to length by the cut-to-length system with cut-to-length knives as an operation following slitting. Guillotine shear blades are used on systems of all reputable manufacturers either in the standard versions or in customized form.

Customer Groups

- Integrated Steel Mills

- Non-Ferrous Metal Processors

- Cold Rolling Mills

- Steel Service Centers

- Pipe and Tube Mills

- Transformer Band Manufacturers

- Surface Profiling Companies

- Packaging Tape Manufacturers

- Metal Packaging Companies

- Steel Grating Manufacturers

- Mechanical Engineering Companies

Slitting Lines Product

Rotary Slitter Knives

Advantages / Characteristics

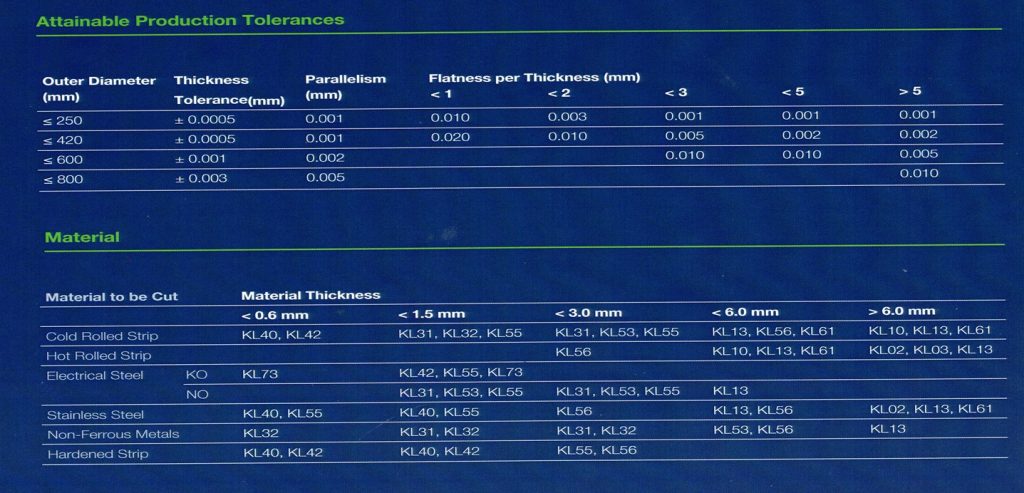

- Adherence to the smallest possible thickness tolerance down to ± 0.0005 mm

- Subdivision of thickness tolerance in 3 areas (–, 0, +)

- 4 highly precise surface finishes

- Suitable for sheet metal thicknesses from 0.006 to approximately 16 mm and in exceptional cases also to 40 mm

- Rotary slitter knives ground with a single-sided facet and an exact edge

Stripper Rings

Stripper rings assist cutting applications for various tasks:

- Ejecting

- Conveying

- Lifting (protecting the material surface)

- Supporting (stabilizing the material)

Rubber Bonded Stripper Rings

Advantages / Characteristics

- Graduated in thickness from 3 to 100 mm (in exceptional cases up to 250 mm)

- Hardness 60 to 95 Shore A

- Different colors

- Special dimensions of steel cores for trimming systems

- Divided spacers

- Special weight saving models

- Excellent oil and abrasion resistance

- Highly resistant to cleaning alcohol

- High precision with thickness tolerances up To +,-0.0005 mm

Steel stripper rings made of hardened alloyedtool steel are used for thin materials and thenarrowest strips, provided the design of theslitting line permits such use.

Polyurethane-bonded steel stripper rings canbe delivered as a special version for cuttingsensitive material.

Steel Stripper Rings

Loose Rubber Rings

Spacers

Standard Models

Advantages / Characteristics

- Graduated in thickness from 0.1 to 100 mm (in exceptional cases up to 250 mm)

- Lateral surfaces are lapped, ground and polished

- Burnished

- Special edge dimensions

- High precision with thickness tolerances up to +,-0005 mm

- Special feed and ejector rings

Lightweight Spacers

Advantages / Characteristics

- High precision with thickness tolerances up to +,-0005 mm

- Tool steel or stainless steel quality

- Utilization of ergonomic advantages

Special Design

TKM has a large range of special design spacers – either divided or as hinged rings.

Advantages / Characteristics

- Divided spacers for subsequent knife clearance corrections

- Quick changing of special gauge spacers

Plastic Shims

Plastic foils in various colors and in predefinedmaterial thicknesses as plastic shimsfacilitate adjustment of the knife clearance.

Separator Tools

The following parts ensure clean separation and guidance of the cut material strips and

smooth winding of the strips onto the recoiler of the slitting line:

- Separator discs made of chrome alloy tool steel

- Separator spacer rings made of polyamide

- Special versions in steel/aluminum with polyurethane coating

Scrap Chopper Knives

The most efficient and reliable solution isshredding or chopping of the waste strips withscrap chopper knives made of high qualityalloy tool steel.

A number of different dimensions – also withspiral sharpening – are available.

Cutting Quills

Advantages / Characteristics

- The TKM guide system maintains the narrowest knife clearance

- Repeat accuracy of the strip widths

- Minimized set-up times

- Our clamping system guarantees the smallest possible axial run-out

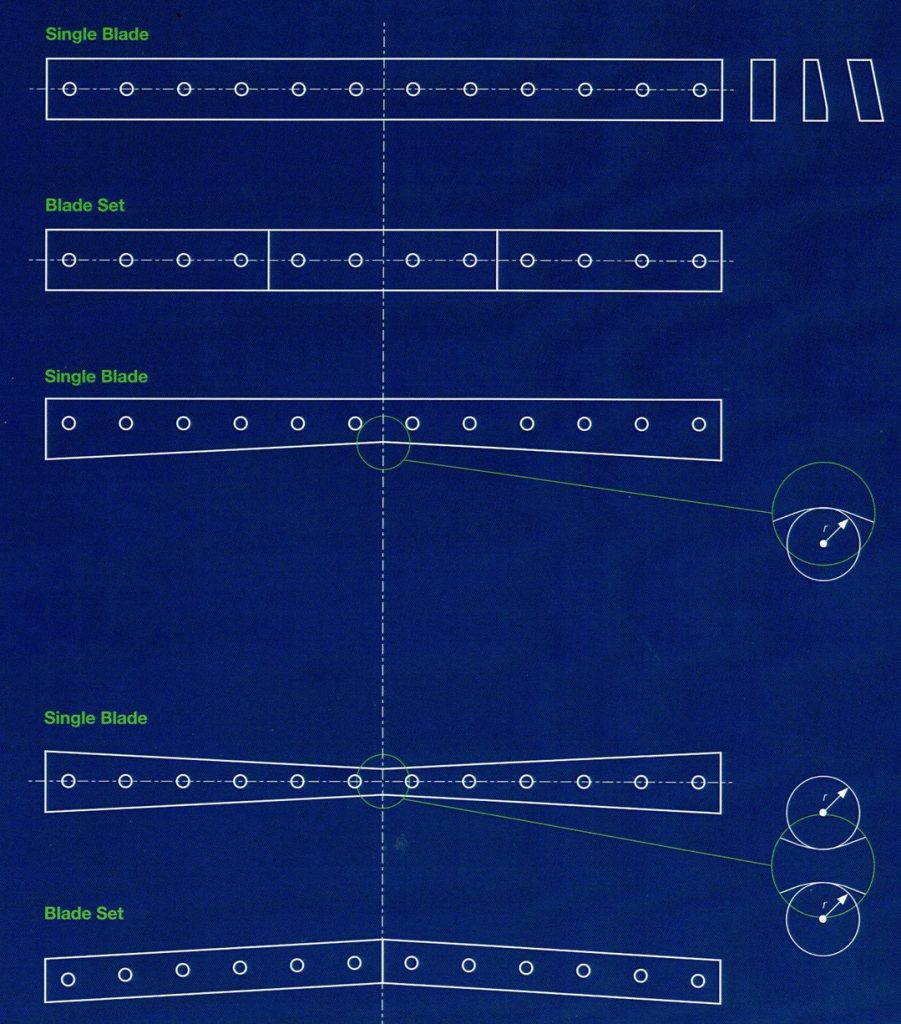

Cut to Length Knives / Guillotine Shear Blades

For cut-to-length lines and for guillotine shears, we produce highly precise knives and shear blades with a length of up to 6000 mm. Production, including heat treatment, is completely in-house. We accordingly guarantee consistently high quality of the knives and shears with the best microstructure and the best mechanical properties. Depending on the requirements, either special tool steel or a special nickel-based alloy is used. In particular, we can handle, as a single source, system-related requirements as well as specific manufacturing processes at the customer’s end, thanks to our in-house production depth.

Advantages / Characteristics

- Knife material and heat treatment are keyed to the material to be cut

- Cross, radial and peripheral grinding possible

- Highest accuracies maintained

- Ground radii for V-shape blades

- Blades for all guillotine shear types